Looking for a way to make your custom headwear stand out in a crowded B2B market, but tired of seeing messy, low-quality 3D foam samples? Subpar embroidery ruins your brand reputation and leads to costly returns.

To achieve precision in 3D embroidery hats, you must combine high-density digitizing with specific machine tension settings and premium foam. Success depends on using “capping” stitches to seal foam edges and choosing structured, high-profile blank hats that can withstand the heavy needle penetration required for a clean, 3D finish.

I have spent years perfecting the balance between machine speed and stitch precision. If you are a bulk buyer, understanding these technical hurdles will help you vet suppliers and ensure your large-scale orders meet retail standards. Let’s dive into the technical roadmap for perfect puff.

1. Which Blank Hats are Best for 3D Foam Precision?

Are you tired of seeing your expensive 3D logos look saggy or distorted because the hat fabric couldn’t handle the tension? Choosing the wrong “canvas” for your embroidery leads to puckering, ruined blanks, and wasted capital on bulk orders.

The best hats for 3D puff embroidery are structured, high-profile snapbacks or fitted caps made from wool blends or heavy acrylic. These materials provide the necessary tension and “push-back” against the foam, ensuring the design stays crisp and the hat maintains its shape during the high-density stitching process.

High-Profile vs. Low-Profile Crowns

When you are placing a bulk order, the crown height is your first major decision. High-profile hats, like the classic 6-panel snapback, feature a stiffened buckram behind the front panels. This internal structure is vital. Without it, the weight of the foam and the thousands of extra stitches required for 3D effects will cause the fabric to collapse. I always recommend structured hats for B2B clients because they offer a consistent flat surface. Low-profile “dad hats” lack this support. If you try to put a thick 3D logo on a floppy cotton dad hat, the fabric will bunch up around the edges of the logo, creating a “bird’s nest” effect on the inside. For precision, the hat needs to act like a rigid frame. You can browse our structured cap collection to see which styles work best for this technique.

Why Fabric Density Matters

Not all fabrics are created equal when it comes to foam. A thin 100% cotton twill might look good for flat embroidery, but it often fails under the pressure of 3D foam. I prefer wool blends or heavy-duty polyester. These synthetic fibers have a “memory” that helps them hold onto the embroidery thread. When the needle punches through the foam into a heavy fabric, the hole stays small. In contrast, loose-weave fabrics can develop “needle scars”—visible holes around the perimeter of your logo. If your brand demands a premium look, do not skimp on the base material. The interaction between the needle, the thread, and the foam is a violent physical process. A heavy-duty fabric absorbs that energy, while a cheap fabric tears.

| Hat Type | Structure | Fabric Compatibility | 3D Puff Suitability |

| Snapback | High-Profile / Structured | Wool Blend / Acrylic | Excellent |

| Dad Hat | Low-Profile / Unstructured | 100% Cotton Twill | Poor (High Risk of Puckering) |

| Trucker Hat | Mid-Profile / Structured | Polyester Mesh / Foam Front | Good (Front Panel Only) |

| Fitted Cap | High-Profile / Structured | Heavy Polyester | Excellent |

When you are vetting a manufacturer, ask them about the “gram weight” of their hat fabric. If they cannot give you a straight answer, they might be using thin materials that won’t hold a 3D stitch well. We focus on durability at SN to ensure that every stitch in a 500-piece order looks exactly like the first sample.

2. Why is Digitizing the Most Critical Step for Quality?

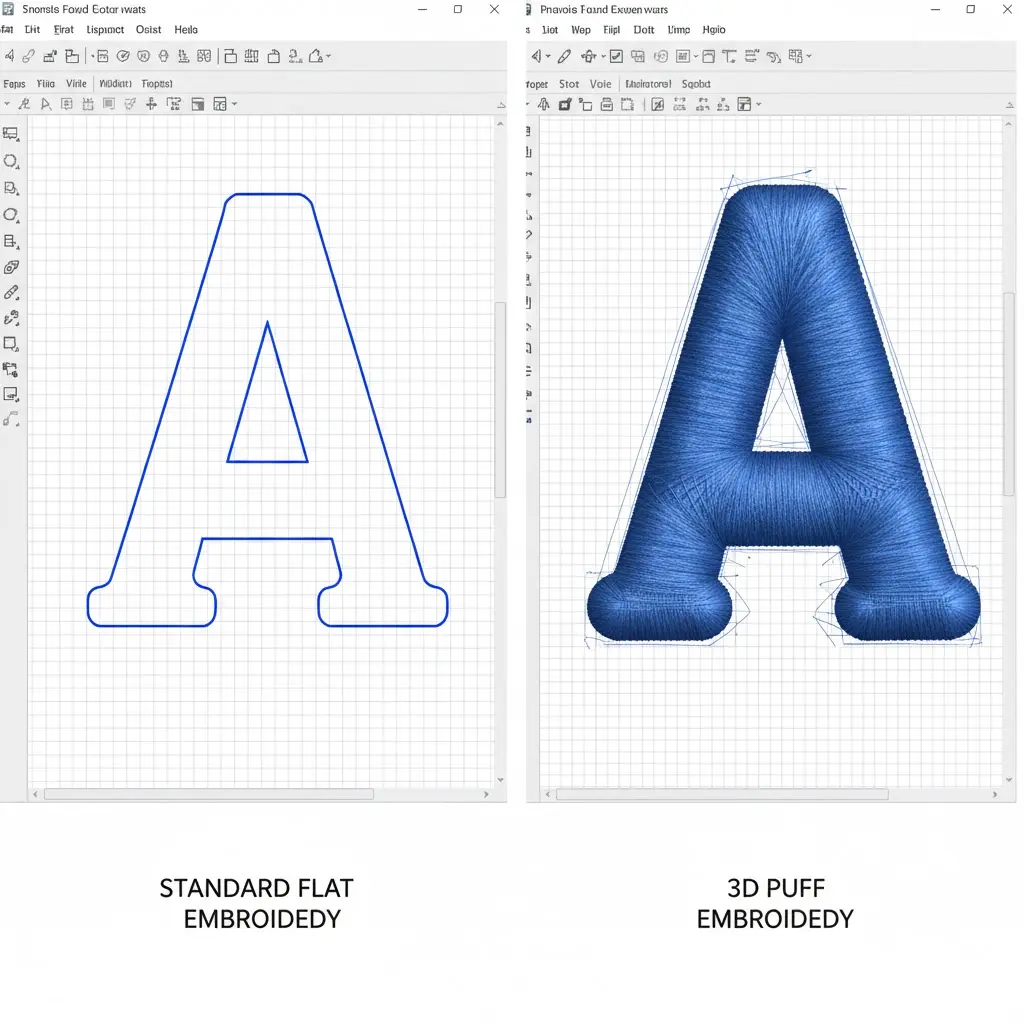

Do you find that your 3D logos often have foam “bleeding” out of the sides, making the finished product look cheap? Most 3D embroidery failures happen before the machine even starts because the digital file was not built specifically for foam.

Proper 3D digitizing requires nearly double the stitch density of flat embroidery and the use of “capping” stitches to seal the ends of letters. This prevents the foam from popping out and ensures that the satin stitches completely wrap around the foam for a smooth, professional finish.

The Logic of “Density is King”

Standard flat embroidery usually has a density of around 0.40mm. For 3D puff, you need to tighten that significantly, often down to 0.20mm or 0.18mm. Think of it like a fence. If the pickets are too far apart, you can see what is behind them. In this case, you see the foam. If the density is too low, the foam will poke through the stitches, especially on curves. However, if the density is too high, the needle will cut the foam into pieces, and the logo will lose its “lift.” It is a delicate balance. I always tell my clients that a 3D logo will have a much higher stitch count—and therefore a higher cost—than a flat one. If a supplier tells you they can do 3D puff with the same stitch count as flat embroidery, they are cutting corners that will result in a messy product.

Mastering Capping and Underlay

The edges of a letter are where most 3D designs fail. If you are embroidering a letter “H,” the top and bottom of the vertical bars are open. Without a “cap,” the foam will stick out of the ends like a sandwich. Digitizers must add a horizontal satin stitch at the ends of these bars to “pinch” the foam down before the main satin stitches cover it. Furthermore, a heavy underlay is required. We use a wide satin underlay to create a foundation. This underlay flattens the foam slightly so the top stitches can glide over it smoothly. This technical detail is what separates a retail-ready hat from a promotional giveaway. Our custom design services focus on these micro-adjustments to ensure your logo looks sharp from every angle.

| Feature | Flat Embroidery | 3D Puff Embroidery | Reason for Change |

| Stitch Density | 0.40mm – 0.45mm | 0.18mm – 0.25mm | To fully cover the foam volume. |

| Underlay | Light zigzag | Heavy Satin / Border | To secure and compress foam edges. |

| Tie-offs | Standard | Extra Long / Secure | To prevent unraveling under tension. |

| Edge Treatment | Open | Capped / Tapered | To hide the foam ends completely. |

As a buyer, you should ask to see the “wireframe” of the digitized file. Look for those extra stitches at the ends of letters. If the file looks too simple, the finished hat will likely have foam sticking out everywhere.

3. How to Choose the Right Foam for Large Orders?

Are you worried that your 3D logos will look inconsistent across a large production run? Using the wrong foam thickness or color can lead to variations that make your bulk order look unprofessional and uncoordinated.

For most commercial headwear, 3mm foam is the industry standard for a balanced look. To achieve a clean finish, you must match the foam color to the thread color as closely as possible to hide any minor “peek-through” that occurs during natural wear and tear.

Understanding Foam Thickness

Foam typically comes in 2mm, 3mm, and 6mm thickness. While it is tempting to go for 6mm for maximum “pop,” it is extremely difficult to execute on most commercial machines. Thick foam creates massive tension on the needle and can lead to frequent thread breaks. For B2B orders where consistency is key, 3mm is the “sweet spot.” It provides enough height to be noticed from a distance but is thin enough that the machine can maintain a high speed without errors. If you go too thin (2mm), the effect is barely noticeable, and you might as well save money by doing flat embroidery. If you are unsure which height fits your brand, you can check our latest project gallery to see the difference between various foam heights.

The Importance of Color Matching

This is a small detail that saves big headaches. Even with high-density stitching, the foam is under pressure. Over time, as a person wears the hat, the thread might shift slightly. If you use white foam under black thread, every tiny gap will look like a mistake. Always use black foam for dark threads and white foam for light threads. If you are doing a vibrant color like red or blue, try to find matching foam. If matching foam isn’t available, we use a trick: we digitize a “floor” of flat stitches in the same color as the thread before laying the foam. This creates a color-matched base so that even if the foam is a different color, it won’t be visible to the end consumer.

| Foam Thickness | Best Use Case | Risk Level |

| 2mm | Subtle branding, small text | Low (Very stable) |

| 3mm | Standard retail logos, snapbacks | Medium (Industry Standard) |

| 6mm | Oversized “streetwear” logos | High (Frequent thread breaks) |

When you order from us, we handle the foam sourcing to ensure the colors align perfectly with your brand’s Pantone requirements. This level of detail is what keeps our B2B partners coming back for repeat runs.

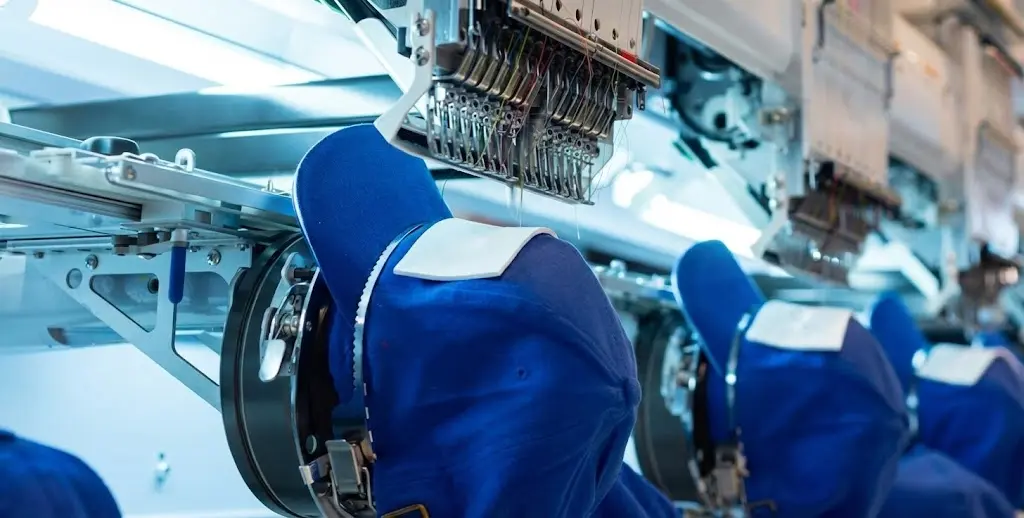

4. Why is Machine Calibration Key to Batch Consistency?

Do you ever wonder why your 3D samples look great but the actual bulk shipment has crooked logos or frayed threads? This usually happens because the embroidery machines weren’t properly calibrated for the extra height of the foam.

Precision 3D embroidery requires a “sharp” needle (75/11 or 80/12) to cleanly cut through the foam and lower top-thread tension. Proper calibration ensures the thread wraps around the foam without pulling too hard, which prevents the hat from warping or the thread from snapping.

Needle Selection: Sharp vs. Ballpoint

In standard embroidery, we often use ballpoint needles to avoid tearing the knit of the fabric. But for 3D puff, you need a sharp needle. Why? Because the needle acts like a cookie cutter. Every time it strikes, it needs to pierce the foam cleanly so that the excess foam can be pulled away easily after the job is done. A dull or ballpoint needle will “push” the foam instead of cutting it, leading to ragged edges. We use premium titanium-coated sharp needles for all our 3D orders. They stay sharp longer and handle the heat of high-speed production better. If your current supplier’s logos have fuzzy edges, they are likely using the wrong needles.

Tension Management for High Volumes

Tension is the most common point of failure. When you add 3mm of foam, you are essentially asking the thread to travel a longer distance for every stitch. If the tension is too tight, the thread will “strangle” the foam, flattening it out and losing the 3D effect. Worse, it can cause the front of the hat to “buckle” or pucker. We manually adjust the tension on every head of our multi-head machines before starting a 3D run. We look for a “loopier” satin stitch that has enough slack to sit on top of the foam without being loose. This requires constant monitoring. A professional factory will have a technician checking the tension every hour. You can learn more about our quality control process on our production page.

| Setting | Standard Embroidery | 3D Puff Adjustment |

| Needle Type | Ballpoint (75/11) | Sharp (75/11 or 80/12) |

| Top Tension | Normal (Approx 110gf) | Loose (Approx 90gf) |

| Bobbin Tension | Standard | Standard (Check for balance) |

| Machine Speed | 800 – 1000 SPM | 500 – 650 SPM |

Lowering the machine speed is also non-negotiable. While it takes longer to produce, it reduces the heat and friction that causes thread breaks. For a B2B buyer, this means a slightly longer lead time but a much higher success rate for the final product.

5. How Does the “Stop and Drop” Method Ensure Accuracy?

Are you concerned about the manual labor involved in 3D embroidery and how it might affect your delivery timeline? Understanding the physical process helps you realize why 3D embroidery is a premium service that requires skilled operators.

The “Stop and Drop” method involves programming the embroidery machine to pause after the underlay is finished so the operator can manually place the foam over the design area. This ensures the foam is perfectly centered and secured before the high-density top stitches begin.

The Importance of the Manual Pause

You cannot just “run” a 3D job from start to finish like a flat logo. The machine must be programmed with a “stop” or “color change” command at a specific point. Our operators then place a piece of foam over the designated area. We don’t use the whole sheet; we cut pieces slightly larger than the logo to minimize waste. If the machine doesn’t stop, the needle might catch the edge of a moving foam sheet, causing a catastrophic jam. This manual intervention is why 3D puff costs more. It requires a person to stand by the machine and interact with it for every single hat in the batch.

Securing Foam on Curved Surfaces

Hats are curved, but foam is flat. This is a recipe for shifting. If the foam moves even 2mm during the stitch-out, the logo will be ruined. We use two main methods to prevent this: light-duty adhesive spray or simple masking tape. For high-end B2B orders, we prefer masking tape on the corners because it leaves no residue on the fabric. The “tack-down” stitch then goes over the foam to hold it firmly in place before the heavy satin stitches start. This step is critical for precision. If a factory is rushing and not securing the foam, you will see “ghosting” where the 3D part of the logo isn’t perfectly aligned with the flat part.

| Step | Action | Purpose |

| 1. Underlay | Machine stitches the “map” | Prepares the fabric and marks foam placement. |

| 2. Pause | Machine stops | Allows operator to place foam. |

| 3. Tack-down | Machine stitches a border | Secures foam to the hat surface. |

| 4. Satin Stitch | Machine covers foam | Creates the actual 3D logo. |

This process ensures that every hat in your 500-unit or 1,000-unit order is identical. If you want to see how we handle large-scale custom orders with this level of care, feel free to contact our sales team for a consultation.

6. What Post-Production Steps are Needed for a Retail Finish?

Do you ever receive 3D embroidered hats that have tiny “hairs” or bits of foam sticking out between the stitches? This is a sign of poor post-production. Even the best machine run needs a human touch to reach retail quality.

A professional retail finish is achieved by using a heat gun to shrink any stray foam particles and manually “picking” out the excess foam from the negative spaces of the logo. These steps ensure that the lines are crisp and no internal foam is visible to the customer.

The Heat Gun Trick

After the embroidery is finished, the operator tears away the excess foam. However, because the foam is perforated by the needle, tiny “crumbs” often remain in the corners of letters like “A” or “O.” We use industrial heat guns set to a specific temperature. When you pass a quick burst of heat over the logo, the foam reacts by shrinking. It retreats under the thread, leaving a perfectly clean edge. But you have to be careful—too much heat will melt the polyester thread or scorch the hat fabric. It takes an experienced hand to do this correctly across thousands of hats without a single mistake.

Manual Picking and Final Inspection

Sometimes the heat gun isn’t enough. For complex logos with tight internal spaces, our team uses specialized tweezers or “nippers” to manually pull out small chunks of foam. This is the “dirty work” of 3D embroidery that many low-cost factories skip. If you are a B2B buyer looking to sell these hats in a retail environment, you cannot afford to have customers seeing foam bits. We perform a 100% inspection on all 3D orders. If a logo isn’t perfect, it doesn’t ship. This commitment to the “final 5%” of the process is what builds trust with our long-term partners.

| Cleaning Tool | Use Case | Result |

| Heat Gun | Removing tiny foam “fuzz” | Clean, sharp stitch lines. |

| Tweezers | Removing foam from “O”, “R”, “B” centers | Clear negative space. |

| Nippers | Cutting stubborn foam bridges | Accurate logo geometry. |

A clean post-production phase is the difference between a hat that stays on the shelf and one that sells out. We take pride in delivering hats that are ready for the showroom floor the moment they arrive at your warehouse.

7. How to Troubleshoot Common 3D Puff Quality Issues?

Are you worried about the “fail rate” of your 3D embroidery orders? High-density stitching on foam increases the risk of thread breaks and “foam peek-through,” which can delay your project if not managed correctly.

Common 3D puff failures like foam peek-through are usually caused by low stitch density or mismatched foam colors. Thread breaks and “bird nesting” are often the result of using needles that are too dull or machine speeds that are too high for the thickness of the foam.

Dealing with Foam Peek-Through

If you see little dots of foam through the stitches, the density is likely too low. However, if the density is already high and you still see foam, the issue might be the “stitch angle.” Satin stitches should always be perpendicular to the foam for maximum coverage. If the angle is too slanted, the foam will slide out between the threads. We solve this during the digitizing phase by adjusting the “auto-spacing” to be tighter on curves. As a buyer, if you see this on a sample, tell your supplier to “increase density by 10% and check the stitch angles.”

Solving Thread Breaks and Bird Nesting

A “bird’s nest” is a massive tangle of thread on the underside of the hat. In 3D embroidery, this usually happens when the needle gets “gummed up” with foam residue or adhesive spray. If the needle can’t pass through cleanly, the bobbin thread won’t catch the top thread correctly. We prevent this by cleaning our needles regularly and using a silicone-based thread lubricant. This allows the thread to glide through the foam without friction. If your supplier is complaining about constant thread breaks, they probably need to slow down their machines or change their needles more frequently.

| Problem | Likely Cause | Solution |

| Foam Peek-Through | Low density / wrong stitch angle | Increase density; adjust angles in digitizing. |

| Thread Breaks | High speed / dull needle | Slow down machine; use sharp 75/11 needles. |

| Bird Nesting | Adhesive buildup / tension issue | Clean needles; adjust bobbin and top tension. |

| Hat Warping | Too much tension | Loosen top tension; use a more structured hat. |

Understanding these technical issues allows you to speak the same language as your manufacturer. Instead of just saying “this looks bad,” you can provide specific feedback that leads to a better second sample and a smoother bulk production run.

8. Is the Extra Cost of 3D Puff Embroidery Worth It?

Are you struggling to justify the higher price of 3D embroidery to your stakeholders or clients? While the per-unit cost is higher, the perceived value and retail margins of 3D headwear far outweigh the initial investment.

3D puff embroidery typically costs 30% to 50% more than flat embroidery due to increased stitch counts, specialized digitizing, manual labor for foam placement, and more intensive post-production cleaning. However, it allows you to position your brand in the premium “streetwear” or “pro-sports” category.

Breaking Down the Labor Costs

When you pay for 3D puff, you aren’t just paying for the foam. You are paying for the time the machine is NOT running while the operator places the foam. You are also paying for the significantly higher stitch count. A logo that takes 5,000 stitches in flat embroidery might take 12,000 stitches in 3D. Since most embroidery factories charge by the “thousand stitches,” the price naturally climbs. Then, you add the manual “picking” and “heat gunning” time. For a B2B buyer, it is important to realize that a “cheap” price on 3D puff usually means the factory is skipping the manual cleaning steps.

Market Positioning and ROI

Even though you pay more, the ROI is often higher. A standard flat-embroidered hat might retail for $20. The same hat with a high-quality 3D puff logo can easily retail for $35 to $45 in the streetwear or sports market. The “perceived value” increases much more than the “actual cost.” For bulk buyers, this means better margins and a more desirable product. If you are building a brand, 3D puff is the most cost-effective way to make your product look “high-end” without changing the actual hat blank.

| Feature | Flat Embroidery | 3D Puff Embroidery |

| Production Speed | Fast | Slow |

| Perceived Value | Standard / Promo | Premium / Retail |

| Typical Retail Price | $15 – $25 | $30 – $50 |

| Durability | Very High | High (Needs care) |

If you are ready to upgrade your product line, we can help you calculate the best price-to-quality ratio for your specific needs. Our team specializes in high-volume 3D orders that maintain that “boutique” quality.

Conclusion

Precision 3D puff embroidery is a technical craft that requires the right hats, expert digitizing, and patient machine operation. By focusing on density, tension, and post-production cleaning, you can deliver premium headwear that justifies a higher price point and builds long-term brand loyalty.