Ever felt uncertain just before a shipment leaves the factory—

wondering if what arrives will truly match what you approved?

For many U.S. brands, quality issues don’t show up as small defects on a report.

They show up as delayed launches, returns, and damaged trust with retailers.

That’s why AQL 2.5 exists: to help buyers control quality risk before it becomes costly.

AQL 2.5 is part of the Acceptable Quality Limit system used during pre-shipment inspections.

It defines how many major defects are allowed in a sampled batch before a shipment is rejected.

In practical terms, choosing AQL 2.5 means this:

buyers may tolerate minor imperfections, but defects that affect function, appearance, or sellability must be tightly controlled.

It’s not about perfection—it’s about setting a clear, measurable line before goods ship.

Understanding what AQL 2.5 means is only the first step.

The real difference comes down to how it’s applied on the factory floor.

In real inspections, problems rarely come from the standard itself—

they come from rushed sampling, vague defect definitions, or inconsistent execution.

That’s where many shipments quietly go wrong.

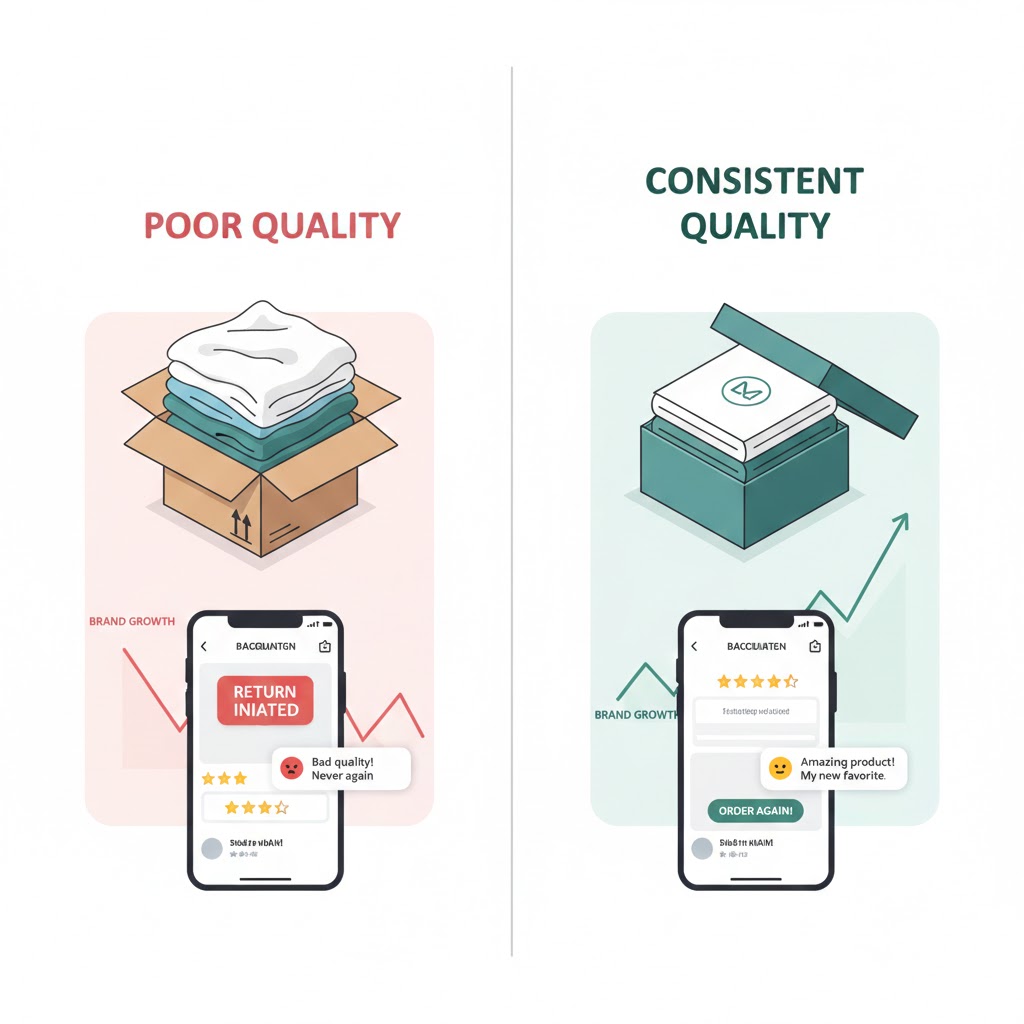

Why One Bad Batch Can Kill Your Brand?

Imagine paying thousands of dollars for a bulk order, only to discover that 20% of the products are unsellable.

The loss isn’t just the invoice.

It’s the delayed launch, the time spent fixing problems, and the trust you lose with customers who were waiting.

This is why experienced B2B buyers worry about the nightmare scenario:

marketing is ready, demand is there—

but when the cartons arrive, the stitching is falling apart.

One bad batch creates hidden costs:

returns, negative reviews, chargebacks, and lost repeat customers.

The reality is that no factory is perfect.

Machines fail. Workers get tired. Mistakes happen.

That’s exactly why standards like AQL 2.5 matter.

They act as a mathematical safety net, clearly defining what level of defects is acceptable—and where the line is crossed—before goods leave the factory.

Without a clear inspection standard, buyers have no solid ground to request a refund or remake.

Only arguments.

By enforcing AQL standards, you signal professionalism to the factory, set clear boundaries, and protect your brand as a long-term asset—

not just a single shipment.

| Risk Factor | Impact on Brand | Financial Impact |

|---|---|---|

| High Defect Rate | Loss of customer trust and repeat business | High (refunds + reshipping) |

| No Inspection Standard | Unpredictable quality, constant disputes | Extremely High (total batch loss) |

| Using AQL 2.5 | Clear expectations and professional reliability | Low (controlled, predictable cost) |

What Exactly is AQL?

Ever wondered how big brands inspect millions of products

without checking every single piece?

They use AQL.

AQL—short for Acceptable Quality Limit—is the bridge between perfect quality and realistic manufacturing costs.

It allows buyers to control risk without slowing production to a crawl.

In simple terms, AQL is a statistical inspection method.

Instead of checking an entire production run, inspectors examine a carefully selected sample size.

That sample provides a statistically valid answer to one key question:

Is this batch good enough to ship?

Buyers often ask, “Why not just inspect every single item?”

The answer comes down to time and money.

If you’re producing 5,000 hats, a 100% inspection can take days.

You pay for extended labor, delays stack up, and your product becomes more expensive before it ever reaches the market.

AQL solves this by using probability.

If a random sample of, say, 200 units meets the standard, the remaining 4,800 are statistically likely to meet it as well.

In B2B procurement, this is known as statistical confidence.

You’re not guessing—you’re managing risk using a system developed by mathematicians and adopted as an industry standard.

That’s why AQL matters in supplier communication.

Saying “we want good quality” is vague.

Saying “we require inspection based on AQL 2.5” is precise—and immediately understood by factories worldwide.

This is also why 100% inspection is often a poor choice:

it drives up cost, increases human error as inspectors fatigue, and makes destructive testing impossible at scale.

Most consumer goods inspections use General Inspection Level II.

It strikes the right balance between accuracy and cost—

giving growing brands reliable quality control without sacrificing their profit margin or supply chain speed.

What Does the AQL 2.5 Number Mean?

Numbers can feel abstract, but in quality control, 2.5 is one of the most practical numbers your business will ever use.

It represents the line between “good enough to ship” and “too risky for your brand.”

In AQL terms, the 2.5 refers to a 2.5% threshold for major defects.

During an inspection, if the number of major defects found in the sample exceeds the acceptance limit tied to this level, the entire batch fails.

Think of AQL 2.5 as your quality budget.

You’re saying: a very small number of mistakes is tolerable—but beyond that, the factory must fix the problem.

For most consumer products, AQL 2.5 is the standard for major defects—issues that affect how a product looks, functions, or can be sold.

It’s strict enough to protect customer experience, but realistic enough for factories to consistently achieve.

Choosing a lower level, like AQL 1.0, means extremely tight control.

This is common for luxury goods or regulated products, where even minor flaws are unacceptable.

Choosing a higher level, like AQL 4.0, is more relaxed.

That may work for low-cost, disposable items—but it often comes at the expense of brand perception.

For growing consumer brands, AQL 2.5 is the sweet spot.

It balances customer expectations, production reality, and long-term brand protection.

In practice, experienced buyers often use a split AQL approach:

zero tolerance for critical safety issues, AQL 2.5 for major functional defects, and a higher level for minor cosmetic flaws.

Putting these exact numbers into your purchase order removes all gray areas.

If the inspection report comes back at 2.6%, the batch fails—no debate, just math.

Comparing AQL Levels for Different Business Needs

| AQL Level | Strictness | Best Use Case |

|---|---|---|

| AQL 1.0 | Very Strict | Luxury brands, high-end tech, regulated products |

| AQL 2.5 | Standard | Consumer brands, headwear, retail products |

| AQL 4.0 | Relaxed | Budget goods, giveaways, disposable items |

Note: Many buyers apply different AQL levels to critical, major, and minor defects within the same product.

Critical, Major, and Minor Defects?

Not every defect carries the same risk.

A loose thread is not the same as a broken needle, and treating them equally can actually hurt your brand rather than protect it.

In quality inspections, defects are typically divided into three categories: Critical, Major, and Minor.

Each category reflects a different level of risk to customer safety, product usability, and brand perception—and each comes with a different AQL limit.

Critical defects are deal-breakers.

These involve safety hazards or legal risks, such as mold on fabric or sharp metal parts inside a hat.

The tolerance for these is almost always zero.

If even one is found, the entire batch fails immediately.

Major defects are issues that make a customer likely to return the product or request a refund—

a crooked logo, a broken strap, or a hole in the fabric.

These are the defects controlled by the 2.5 in AQL 2.5.

Minor defects are small cosmetic imperfections that most customers won’t notice or won’t care about,

such as a loose thread on the inside of the sweatband.

These are usually allowed at a higher level, often AQL 4.0.

The key is clarity.

Experienced buyers don’t leave defect classification up to interpretation—they define it in advance.

A clear defect classification list ensures inspectors, factories, and buyers are aligned, and that the inspection report reflects your brand standards, not the factory’s assumptions.

Defect Classification Example Table

| Defect Type | Example | Typical Acceptance Limit |

|---|---|---|

| Critical | Mold, needles, sharp edges | 0 |

| Major | Incorrect logo, broken strap | AQL 2.5 |

| Minor | Loose thread, small color spot | AQL 4.0 |

Note: Many brands apply different AQL levels to different defect categories within the same product.

How to Read the AQL Table?

At first glance, the AQL table looks like a wall of numbers.

But once you know how to read it, it becomes one of the most powerful tools in your procurement toolkit.Reading an AQL table always follows the same logic.

You’re looking for just three things: your sample size, the accept number (Ac), and the reject number (Re).Step one is finding your Sample Size Code Letter.

Based on your total order quantity (lot size), you look it up under General Inspection Level II.

For example, if your order is 3,000 hats, the table assigns a code letter such as K.Step two is reading the main AQL table.

You find letter K on the left, then move across to the AQL 2.5 column.

This tells you two numbers—Ac and Re.In this example, letter K means a sample size of 125 pieces.

Under AQL 2.5, you may see Ac 7 / Re 8.That means:

if the inspector finds 7 or fewer major defects, the batch passes.

If they find 8 or more, the batch fails.There is no gray area.

This is why experienced buyers rely on the AQL table instead of arguments or emotions.

When it’s written into your purchase order, the table becomes the backbone of your contract.

If the report says “Pass,” payment proceeds.

If it says “Fail,” the factory fixes the goods before getting paid.

That clarity is how large B2B buyers manage multiple suppliers without inspecting every single product.

Example: How One AQL Decision Works

| Item | Example Value |

|---|---|

| Lot Size | 3,000 units |

| Inspection Level | General Inspection Level II |

| Code Letter | K |

| Sample Size | 125 pcs |

| AQL Level | 2.5 (Major Defects) |

| Accept (Ac) | 7 |

| Reject (Re) | 8 |

If defects ≤ 7 → Pass | If defects ≥ 8 → Fail

Why Every E-commerce Brand Needs an AQL Strategy?

In e-commerce, you’re only as good as your last shipment.

One bad batch doesn’t just hurt quality—it wastes your ad spend, damages reviews, and slows growth.

That’s why an AQL strategy matters.

It’s not just a quality tool; it’s a way to protect your marketing investment and brand momentum.

Many brands fail at this stage for a simple reason:

they approve a perfect sample and assume mass production will look the same.

But production at scale is different.

Without a clear AQL 2.5 standard, you’re not managing risk—you’re gambling with it.

An AQL strategy gives you leverage.

When an inspection fails, you’re not arguing opinions—you’re enforcing an agreed standard.

That report allows you to say, “These goods don’t ship until the major defects are fixed.”

Most factories comply, because payment depends on passing inspection.

Without that standard, goods often ship anyway—and the cost lands on you.

Not just in unsellable inventory, but in returns, refunds, and damaged seller metrics.

On platforms like Amazon or Shopify, a handful of quality complaints can hurt rankings fast.

Customers don’t care why something went wrong—they only judge what arrives at their door.

AQL works as a filter.

It catches a factory’s “bad week” before it reaches your customers,

giving you the confidence to scale ads, replenish inventory, and grow without fear of returns flooding your fulfillment center.

Simply put, inspection costs are predictable.

Reputation damage is not.

For any e-commerce brand that plans to scale, an AQL strategy isn’t optional—it’s foundational.

How to Implement AQL 2.5 in 3 Steps

Implementing AQL 2.5 doesn’t require a complex system.

It requires three things: an independent check, clear rules, and contractual clarity.

Step one: use a third-party inspection service.

Never rely on a factory to inspect its own work. An independent inspector provides objective results and removes bias. The cost is small compared to the risk of shipping unsellable goods.

Step two: define your defect list in detail.

Vague rules create disputes. Clear definitions prevent them. Instead of saying “no stains,” specify size limits and visual examples. A simple quality manual—with photos of acceptable vs. unacceptable issues—gives inspectors and factories the same reference point before production even begins.

Step three: make AQL 2.5 part of your purchase order.

State clearly that final payment depends on passing an AQL 2.5 inspection. This changes behavior immediately. When quality is tied to payment, factories pay attention throughout the entire production run.

Follow these three steps, and you stop relying on trust alone.

You move to a system where quality is verified, documented, and enforced.

Common Myths About AQL 2.5

AQL is often misunderstood, which leads to bad decisions.

Let’s clear up the most common myths.

One frequent misconception is: “AQL 2.5 means I accept 2.5% defective products.”

That’s not how AQL works.

AQL 2.5 is a limit, not a target.

It defines the maximum risk you’re willing to tolerate in a sample—not what you expect to receive. In reality, batches that pass AQL 2.5 often have far lower defect rates.

Another myth is that AQL only applies to complex products like electronics.

In practice, apparel and accessories fail just as often—through color bleeding, size inconsistency, or poor workmanship.

Consistency matters whether a product costs $10 or $500.

AQL doesn’t guarantee perfection.

What it guarantees is control—a way to catch serious issues before they reach customers and damage your brand.

Common AQL Myths vs. Reality

| Myth | Reality |

|---|---|

| AQL 2.5 means 2.5% defects are acceptable | It’s a statistical limit, not a target |

| AQL is too expensive for small brands | It’s cheaper than one failed shipment |

| Factories hate inspections | Professional factories prefer clear rules |

| AQL guarantees perfect quality | It manages risk; it doesn’t eliminate it |

Conclusion

AQL 2.5 is the most practical way to balance cost, quality, and scale.

It protects your profit margins, your customer experience, and your brand reputation.

Instead of guessing, you inspect.

Instead of arguing, you rely on standards.

For brands that want long-term growth, AQL isn’t a technical detail.

It’s a business discipline.

If you’re evaluating suppliers or building your first inspection standard, understanding AQL 2.5 is a solid place to start.

FAQ

Q1: Does AQL 2.5 mean I’m accepting 2.5% defective products?

A: No. AQL is a statistical limit, not a target. It defines the maximum risk level in a sample, not the expected defect rate of the entire batch.

Q2: Do I need AQL inspection for small orders?

A: If the order is important to your brand or customers, yes. Smaller orders often carry higher risk because there is less room to absorb mistakes.

Q3: Can a shipment pass AQL and still have minor defects?

A: Yes. AQL is designed to catch major and critical issues. Minor cosmetic flaws may still exist, which is why defect classification matters.

Q4: Who pays if the batch fails AQL inspection?

A: This should be defined in your purchase order. In most professional setups, the factory bears the cost of rework and re-inspection.

Q5: Is AQL enough on its own?

A: AQL is a safety net, not a replacement for good production management. It works best when combined with clear specifications and communication before production starts.