Custom hat manufacturing is rarely a single production step.

It is a sequence of tightly connected decisions — from how a digital design is interpreted, to how panels are cut, embroidered, and shaped into a finished form.

For buyers, the risk is not that these steps are complex.

It is that most of them happen out of sight.

When design interpretation, material handling, or structural shaping is not clearly defined early, problems do not show up immediately. They surface later — during bulk production, quality checks, or even after delivery.

That is why understanding the full custom hat manufacturing process matters.

Not to master factory techniques, but to recognize where inconsistency actually begins — long before a finished hat reaches the U.S. market.

How Does the Custom Hat Manufacturing Floor Actually Operate?

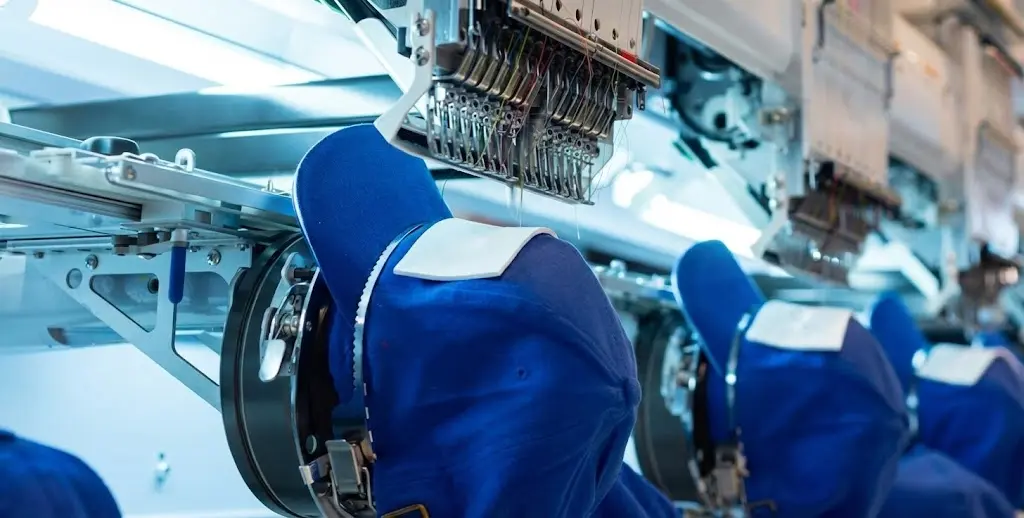

To most buyers, a custom hat manufacturing floor looks busy but opaque.

Machines run, operators move fast, and finished hats appear at the end of the line.

What’s easy to miss is that a manufacturing floor doesn’t produce consistency by default.

Consistency only exists when workstations are organized around clearly defined responsibilities, not just high-speed output.

Modern production floors divide the process into specialized stations, each responsible for controlling a specific risk:

- how panels are aligned before joining

- how structure is reinforced to maintain shape

- how stitching tension is managed on different fabrics

If these controls aren’t defined and synchronized, speed simply amplifies variation — especially across styles like dad hats and structured snapbacks.

The biggest misconception buyers have is assuming that “professional equipment” guarantees uniform results.

In reality, results depend on whether every station is working from the same locked reference, long before final assembly.

During high-speed sewing, problems don’t usually come from lack of effort.

They come from lack of control.

On a well-managed floor, supervisors monitor calibration and workflow timing because even small tension shifts can cause puckered seams on premium fabrics.

Alignment tools and jigs are used not to make production faster, but to ensure every panel enters the process the same way.

When this oversight is missing, bulk shipments may still look acceptable at first glance —

until they’re compared side by side with the approved pre-production sample.

Understanding how a custom hat manufacturing floor operates isn’t about learning machines.

It’s about knowing where consistency is protected — and where it’s often lost.

Precision Assembly Stations (What Buyers Rarely See)

Specialized stations are not about complexity.

They exist to prevent avoidable variation when volume increases.

The question buyers should ask isn’t what machines are used, but what each station is responsible for controlling.

Table 1|What Each Production Station Is Actually Controlling

| Production Station | What It Controls | If This Isn’t Defined, What Happens |

|---|---|---|

| Panel Joining | Final silhouette and symmetry | Bulk hats feel different from samples |

| Crown Reinforcement | Long-term shape retention | Hats lose structure after wear or shipping |

| Stitching Operations | Surface appearance and durability | Puckered seams, uneven finish |

| Seam Coverage | Internal stability and comfort | Early wear issues, reduced lifespan |

| Eyelet Placement | Ventilation consistency | Misaligned or inconsistent airflow |

Equipment Doesn’t Create Consistency — Control Does

High-speed machines matter, but they don’t make decisions.

Different fabrics — from heavy buckram to lightweight performance mesh — behave differently under tension and speed.

Without clearly defined handling rules, equipment simply repeats inconsistency faster.

Table 2|Why Equipment Alone Doesn’t Guarantee Predictable Results

| Buyer Assumption | What Actually Determines Results |

|---|---|

| Advanced machines ensure quality | Locked standards before production |

| Skilled workers prevent variation | Defined tolerances at each station |

| Final inspection protects output | Early-stage control prevents defects |

| Approved samples guarantee bulk | Sample approval criteria are clearly defined |

Key Takeaway

A well-organized custom hat manufacturing floor isn’t defined by how busy it looks.

It’s defined by how many decisions are already made before sewing begins.

When those decisions are clear, bulk production behaves predictably.

When they’re not, inconsistency isn’t an accident — it’s the outcome.

What is the typical custom hat manufacturing timeline?

For many buyers, a custom hat manufacturing timeline sounds simple:

place an order, wait a few weeks, receive finished hats.

In reality, timelines don’t break because factories are slow.

They break because early stages aren’t aligned.

A typical custom hat manufacturing cycle often spans four to eight weeks, depending on design complexity and seasonal capacity. But the biggest variable isn’t sewing speed — it’s how clearly decisions are made before production begins.

When tech packs are incomplete, materials aren’t locked, or samples aren’t approved against clear standards, time doesn’t disappear gradually.

It disappears suddenly — through rework, re-approval, and missed shipping windows.

Buyers also underestimate non-production time.

Physical sample transit alone can consume over a week between factory dispatch and U.S. arrival, turning “fast decisions” into delayed launches if approvals stall.

Understanding the internal timeline isn’t about rushing factories.

It’s about knowing where delays actually originate — long before bulk sewing starts.

Once bulk production is authorized, timelines feel more predictable — but only if earlier steps were controlled.

Mass production often takes around three weeks, but that window depends on synchronized processes such as embroidery scheduling and assembly order. Decoration typically happens before full crown construction so alignment stays consistent across the batch.

If these internal milestones aren’t understood, buyers may assume delays happen randomly.

In practice, delays usually trace back to unclear approvals or late changes, not execution speed.

A realistic timeline allows procurement and marketing teams to plan launches with confidence — without last-minute firefighting.

Table 1|Where Time Is Actually Spent in Custom Hat Manufacturing

| Timeline Phase | What Happens Here | If This Is Rushed or Unclear |

|---|---|---|

| Design & Tech Pack Alignment | Specs, structure, materials are defined | Rework delays and sample revisions |

| Sampling & Approval | Physical reference is validated | Bulk doesn’t match expectations |

| Material Sourcing | Fabrics and trims are locked | Substitutions cause inconsistencies |

| Bulk Production | Sewing and decoration at scale | Speed amplifies earlier mistakes |

| Packing & Dispatch | Final checks and shipment prep | Missed delivery windows |

Critical Production Milestones Buyers Should Understand

Timelines become stressful when milestones are invisible.

Clear checkpoints don’t make production faster —

they make delays predictable instead of surprising.

Table 2|Typical Custom Hat Manufacturing Milestones

| Milestone | Typical Duration | What It Confirms |

|---|---|---|

| Digital Mockup Approval | 1–2 Days | Design intent is aligned |

| Physical Sample Creation | ~7 Business Days | Structure and materials work |

| Sample Shipping & Review | ~7–10 Days | Real-world evaluation |

| Bulk Sewing & Decoration | ~18–24 Days | Scaled execution |

| Finishing & Packing | 3–5 Days | Shipment readiness |

Key Takeaway

The safest assumption in custom hat manufacturing is not “as fast as possible,”

but “as clear as possible.”

Planning around a six- to eight-week window isn’t conservative —

it’s realistic.

When early decisions are defined, timelines compress naturally.

When they’re not, even aggressive schedules fail.

Time doesn’t slip because production is slow.

It slips because clarity arrives too late.

Which materials drive custom hat manufacturing?

The safest assumption in custom hat manufacturing is not “as fast as possible,”

but “as clear as possible.”

Planning around a six- to eight-week window isn’t conservative —

it reflects how real production timelines behave when early decisions are made correctly.

When specifications, materials, and approval standards are defined upfront, timelines often compress on their own.

When they aren’t, even the most aggressive schedules fail under revision cycles, re-approvals, and late-stage changes.

Time doesn’t slip because factories work slowly.

It slips because clarity arrives too late — after production has already begun.

Timeline Assumptions vs. Reality

| Common Buyer Assumption | What Actually Affects the Timeline |

|---|---|

| Faster orders mean faster delivery | Early clarity reduces rework |

| Tight schedules prevent delays | Undefined specs create revisions |

| Production speed controls timing | Decision timing controls outcomes |

| Delays happen on the factory floor | Most delays start before sewing |

Why does custom hat manufacturing face failures?

Failures in custom hat manufacturing rarely start on the sewing line.

They usually begin earlier — when critical details are assumed instead of clearly defined.

A small misunderstanding during tech pack translation — such as crown height or brim width — doesn’t stay small once production scales. When those details aren’t physically confirmed before bulk assembly, the result is often an entire run that looks “almost right,” but can’t be sold.

Skipping or rushing the sampling phase increases this risk.

Without a clear reference point, issues like crooked logos or inconsistent sizing aren’t caught early — they only appear after hundreds of units are already completed.

Material behavior is another frequent failure point.

Fabric shrinkage, dye bleeding, or color transfer don’t always show up in early handling. They emerge after wear, moisture exposure, or washing — when it’s too late to fix them.

Most manufacturing failures aren’t surprises.

They’re the predictable outcome of decisions that were never fully locked.

Common Failure Points in Custom Hat Manufacturing

| Failure Area | What Goes Wrong | Why It Happens |

|---|---|---|

| Design Translation | Shape or sizing feels “off” | Specs interpreted, not confirmed |

| Sampling | Bulk differs from sample | Sample approval too loose |

| Materials | Warping or dye migration | Fabric behavior not tested |

| Decoration | Crooked or fraying logos | Alignment standards unclear |

| Components | Breakage after use | Durability not validated early |

Key Takeaway

Manufacturing failures don’t happen because factories are careless.

They happen because details were never locked before scale.

When specifications, samples, and material behavior aren’t clearly defined, problems don’t disappear — they multiply.

In custom hat manufacturing, prevention isn’t about tighter inspections.

It’s about making sure there’s nothing left open to interpretation before production begins.

Why is quality control mandatory in custom hat manufacturing?

Quality control in custom hat manufacturing isn’t about catching small flaws.

It’s about preventing brand-level damage before products ever reach the market.

Most defects that trigger customer complaints — crooked visors, uneven stitching, weak closures — aren’t always obvious during production. They surface after shipping, handling, or first use. When quality checks only happen visually or too late, problems slip through at scale.

That’s why final-stage inspections matter.

Not because factories lack skill, but because remote production leaves no second chance once goods are shipped.

Without structured quality control, buyers often discover issues only after cartons arrive — when fixes are expensive, timelines are broken, and inventory becomes unsellable.

Quality control doesn’t slow production.

It prevents mistakes from becoming irreversible.

What Quality Control Is Actually Protecting

| Risk Area | What Can Go Wrong Without QC | Business Impact |

|---|---|---|

| Stitching & Shape | Crooked visors, uneven seams | Returns and negative reviews |

| Structural Strength | Snaps or buttons fail in use | Brand trust erosion |

| Interior Finishing | Sharp edges or loose threads | Customer complaints |

| Color Accuracy | Dye transfer or mismatch | Unsellable inventory |

| Packaging & Labeling | Damage in transit | Delayed launches |

Key Takeaway

Quality issues don’t hurt because they exist.

They hurt because they reach customers.

In custom hat manufacturing, quality control isn’t an extra step —

it’s the last opportunity to prevent small defects from becoming public failures.

Once products ship, control ends.

What’s caught before shipment protects everything that follows.

How can brands vet a custom hat manufacturing partner?

Vetting a custom hat manufacturing partner starts by looking past polished websites and sales promises.

What matters isn’t how a factory presents itself — but how much of its operation it’s willing to show.

Reliable partners don’t hesitate to share basic proof: business registration, recent compliance audits, and physical samples from past production. These aren’t formalities. They’re signals of whether a supplier operates as a real manufacturer or simply brokers orders downstream.

Another critical test is technical communication.

A true manufacturing partner can explain trade-offs — such as brim materials, embroidery methods, or construction choices — based on your price point and end use. Vague answers, delayed responses, or resistance to transparency often indicate limited control over actual production.

The biggest risk isn’t choosing a factory that lacks capability.

It’s choosing one that can’t clearly explain how decisions are made once production starts.

Partner Vetting: What to Check — and Why

| Verification Area | What to Look For | If This Is Missing |

|---|---|---|

| Legal & Compliance | Valid registration, recent audits | Unclear accountability |

| Sample Evidence | Retail-ready past production | Quality claims can’t be verified |

| Technical Dialogue | Clear pros/cons explanations | Design intent gets lost |

| Factory Access | Address or virtual access | Likely middleman |

| Process Transparency | Willingness to explain QC | Hidden risks surface later |

Key Takeaway

The right partner isn’t the one who promises the most.

It’s the one who’s willing to be examined.

In custom hat manufacturing, transparency isn’t a courtesy —

it’s the clearest indicator of control.

When a supplier welcomes scrutiny, surprises become rare.

When they don’t, problems usually arrive after production begins.

What role does steam play in custom hat manufacturing?

In custom hat manufacturing, steam isn’t a cosmetic step.

It’s what turns a sewn fabric shell into a hat that actually holds its shape.

Without proper steam blocking, hats may look acceptable right off the line —

but they lose structure quickly once shipped, stacked, or worn. Wrinkling, crown collapse, and uneven height often trace back to this stage.

Steam temporarily softens the fibers so they can be shaped against a fixed form.

What matters to buyers isn’t the machinery itself, but whether heat and moisture are applied evenly and consistently across the batch.

Just as important is what happens next.

If cooling is rushed or uneven, the shape doesn’t fully set. Problems then appear later — inside shipping containers, on retail shelves, or after the first few wears.

Steam blocking doesn’t make hats look better in the moment.

It determines whether they stay retail-ready over time.

Steam Blocking: What It Actually Controls

| Process Variable | What It Controls | If This Is Mishandled |

|---|---|---|

| Steam Application | Fiber flexibility for shaping | Wrinkles, weak structure |

| Mold Accuracy | Crown height and silhouette | Inconsistent fit |

| Moisture Distribution | Surface finish | Water spots or fabric damage |

| Cooling Method | Shape memory | Warping after shipping |

| Cycle Consistency | Batch uniformity | Size and height variation |

Key Takeaway

Steam blocking isn’t about making hats look finished.

It’s about making their shape predictable after shipping, storage, and wear.

In custom hat manufacturing, poor blocking doesn’t fail immediately.

It fails later — when correction is no longer possible.

What logistics rule custom hat manufacturing?

In custom hat manufacturing, logistics rarely fail because shipping is complex.

They fail because costs, timelines, and responsibilities aren’t clearly defined upfront.

Bulk headwear is lightweight but voluminous, which means freight decisions affect margins more than many buyers expect. When duties, port charges, or last-mile delivery responsibilities aren’t clarified in advance, surprises tend to appear only after the goods arrive.

Shipping mode is another common source of miscalculation.

Ocean freight offers the lowest cost per unit, but it introduces longer transit times and exposure to port congestion or weather delays. Air options reduce transit time, but quickly erode profitability if used reactively.

Logistics doesn’t break when ships move slowly.

It breaks when inventory planning and shipping decisions are misaligned with real lead times.

Understanding logistics isn’t about mastering freight terms.

It’s about knowing which choices lock in predictability — and which ones introduce risk.

Logistics Decisions That Shape Cost and Risk

| Decision Point | What It Affects | If Not Planned Clearly |

|---|---|---|

| Shipping Responsibility | Final landed cost | Unexpected invoices |

| Freight Method | Cost vs. speed balance | Margin erosion |

| Transit Time Assumptions | Inventory availability | Missed launches |

| Carton Optimization | Freight charges | Paying for empty space |

| Delivery Coordination | Arrival timing | Delays after port arrival |

Key Takeaway

Logistics isn’t a shipping problem.

It’s a planning problem.

In custom hat manufacturing, predictable margins depend on predictable logistics decisions —

made before production finishes, not after goods are ready to ship.

When logistics are defined early, shipping becomes routine.

When they’re not, costs and delays surface when options are already limited.

Which closures work best for custom hat manufacturing?

In custom hat manufacturing, closures aren’t a minor detail.

They directly affect fit, comfort, and how “premium” a hat feels the moment someone puts it on.

The problem isn’t choosing the wrong closure type —

it’s choosing one without considering how the hat will actually be used.

Snapbacks and sliders are popular because they support “one size fits most,” making them practical for wholesale, promotions, or corporate gifting. But durability matters. Poor-quality plastic snaps can crack in cold weather, while low-grade metal buckles may slip or corrode over time.

Closures also influence perception.

A metal buckle suggests longevity and lifestyle positioning, while a plastic snapback signals casual or streetwear intent. When closure choice isn’t aligned with fabric, structure, or audience, even a well-made hat can feel mismatched.

Closures don’t fail loudly.

They fail after repeated use — when replacements aren’t an option.

Closure Choices: What Buyers Should Consider

| Closure Type | Best Use Case | If Poorly Chosen |

|---|---|---|

| Plastic Snapback | Promotions, streetwear | Cracking or loss of tension |

| Metal Buckle | Lifestyle, premium retail | Slipping or corrosion |

| Hook & Loop | Utility, workwear | Worn grip over time |

| Leather Strap | Boutique, fashion | Premature wear if untreated |

Key Takeaway

Closures don’t just adjust fit.

They define how a hat feels after months of use.

In custom hat manufacturing, hardware quality is rarely noticed when it works —

but immediately felt when it fails.

Choosing the right closure isn’t about style preference.

It’s about ensuring the hat performs as expected, long after delivery.

How can brands scale via custom hat manufacturing?

Scaling through custom hat manufacturing isn’t just about producing more units.

It’s about shifting from convenience-driven decisions to system-driven ones.

Many brands begin with domestic blanks because they’re fast and familiar.

But as volume grows, those same blanks limit differentiation, margin, and long-term control. Scaling requires moving from “what’s available” to “what’s defined.”

The real advantage of offshore custom production isn’t customization itself.

It’s repeatability. When design details, materials, and construction choices are clearly documented, brands can expand their product line without re-learning the same lessons at every new volume level.

Cost savings from higher MOQs matter — but only when consistency holds.

Without defined standards, scaling doesn’t multiply success.

It multiplies variation.

Growth also changes what matters operationally.

Early-stage brands can rely on memory and informal decisions.

Scaled brands can’t.

As order volumes increase, consistency depends on whether design intent is captured in documentation — not just understood by a few people. Brands that fail to systemize early successes often find that what worked at 300 units breaks at 3,000.

Scaling isn’t about chasing the largest order possible.

It’s about building a supply chain that behaves predictably as volume increases.

Scaling Decisions That Actually Matter

| Growth Stage | What Changes | Risk If Not Prepared |

|---|---|---|

| Early Runs | Learning what works | Repeating early mistakes |

| Mid-Scale | Margin and consistency | Quality drift |

| Large Volumes | Process dependency | Supply chain instability |

| Line Expansion | Multiple styles/fabrics | Loss of brand coherence |

| Long-Term Scale | System reliability | Growth stalls |

Key Takeaway

Scaling doesn’t fail because brands grow too fast.

It fails because systems don’t grow with them.

In custom hat manufacturing, true scale is reached when results stay consistent —

even as volume, styles, and complexity increase.

Growth isn’t about doing more.

It’s about repeating success without relying on luck.

Frequently Asked Questions Custom Hat Manufacturing — Buyer Clarifications

Can a physical sample be reviewed before bulk production?

Yes — and it’s critical.

Bulk production should never begin without a physical pre-production sample that represents the exact execution standard. Without a confirmed sample, details like embroidery tension, color tone, or structure are left to interpretation, which often leads to mismatches at scale.

How can color accuracy be maintained across different batches?

Color consistency depends on whether color standards are formally defined and verified.

Using a recognized reference system (such as Pantone) is only effective when colors are checked under controlled lighting conditions. Without this step, fabrics and threads may appear acceptable in one environment but differ noticeably in real-world retail settings.

What should buyers know about shipping to the United States?

Shipping risks usually come from unclear responsibility, not transportation itself.

If duties, customs clearance, and final delivery terms aren’t clearly defined upfront, unexpected costs and delays often surface after goods arrive at the port. Predictable logistics start with clearly assigned responsibility before production finishes.

What order quantities make full custom manufacturing viable?

Full custom manufacturing typically becomes stable when volumes support consistent material sourcing and process control.

At very low quantities, customization options may be limited and variation risk increases. Understanding how volume affects consistency is more important than chasing the lowest possible minimum.

Can interior labels and seam tape be customized?

Yes — but only when interior branding is specified as part of the production standard.

When these details are treated as optional or added late, consistency often breaks down. Interior elements should be defined early if they are expected to appear uniform across the entire shipment.