When brands start exploring custom hats, the biggest challenge is rarely design — it’s execution.

Turning a sketch or mood board into a retail-ready cap requires more than choosing a silhouette or fabric. It means navigating minimum order quantities, material sourcing, sampling accuracy, and communication gaps that can quietly derail a launch timeline.

Many founders discover this the hard way: a factory that looks good on paper but goes silent after sampling, or costs that spiral once production begins. If you’re trying to move from concept to inventory without burning cash or momentum, the process behind your custom hats matters just as much as the design itself.

What is the first step to design custom hats?

The first step in designing custom hats isn’t choosing fabric or finalizing measurements — it’s eliminating ambiguity.

Most production issues don’t come from bad ideas, but from unclear instructions that force factories to guess. That’s where many brands lose time, money, and momentum before production even begins.

A detailed tech pack becomes critical at this stage. It translates your creative intent into a shared language the factory can execute without interpretation, reducing costly revisions and sample delays.

Mastering the Tech Pack

Your tech pack is the single most important document in the manufacturing process because it removes gA tech pack is the single most important document in the custom hat manufacturing process because it removes guesswork from production. Without it, even experienced factories are forced to make assumptions — and those assumptions rarely align perfectly with your original design intent.

For custom hats, a well-built tech pack defines exactly how the product should be made, not just how it should look. It gives the production team a clear reference point for fit, proportions, materials, and branding placement, ensuring consistency from the first sample to full-scale production.

At a minimum, a reliable tech pack should clearly specify:

- Crown height and profile depth to control overall fit and silhouette

- Brim width and curvature to maintain visual balance and wearability

- Panel structure and measurements to ensure uniform construction

- Fabric type, weight, and composition to avoid unexpected texture or durability issues

- Pantone color codes for all components to guarantee accurate brand color matching

- Logo size, placement, and application method (embroidery, patch, print, etc.)

When any of these details are missing or loosely defined, manufacturers must fill in the gaps themselves. This often leads to sample revisions, misaligned expectations, and extended development timelines — especially for brands producing custom hats for the first time.

A strong tech pack does more than prevent mistakes. It speeds up communication, shortens sampling cycles, and creates a repeatable standard that can be reused across future designs. Instead of renegotiating specifications with every new order, you build a system that allows your designs to scale with far fewer production surprises.

Visualizing the Concept

Before moving into physical sampling, visualizing your custom hat design digitally helps prevent misinterpretation between you and the factory. This step isn’t about aesthetics — it’s about alignment.

Digital mockups allow you to test logo placement, proportions, and color contrast on the actual hat silhouette before materials are cut. Small issues that seem minor on paper often become costly once stitched, and catching them early can save multiple rounds of sampling.

Effective visualization usually includes vector artwork, silhouette-based mockups, and clear placement references. When shared alongside the tech pack, these visuals give manufacturers a concrete target to follow, reducing back-and-forth communication and helping samples come back closer to spec the first time.

The real purpose of a strong technical foundation isn’t perfection — it’s risk control.

Clear specifications reduce rework, protect your timeline, and help your first sample come back closer to production-ready.

| Technical Element | Why It Matters | What It Protects You From |

|---|---|---|

| Tech Pack | Aligns all production details | Costly revisions and misinterpreted designs |

| Precise Measurements | Locks in fit and proportions | Inconsistent samples and sizing issues |

| Pantone Color Specs | Standardizes color references | Off-brand colors and approval delays |

Time spent clarifying details upfront isn’t overhead — it’s insurance.

Clear planning reduces rework, protects your launch timeline, and makes future custom hat designs far easier to scale.

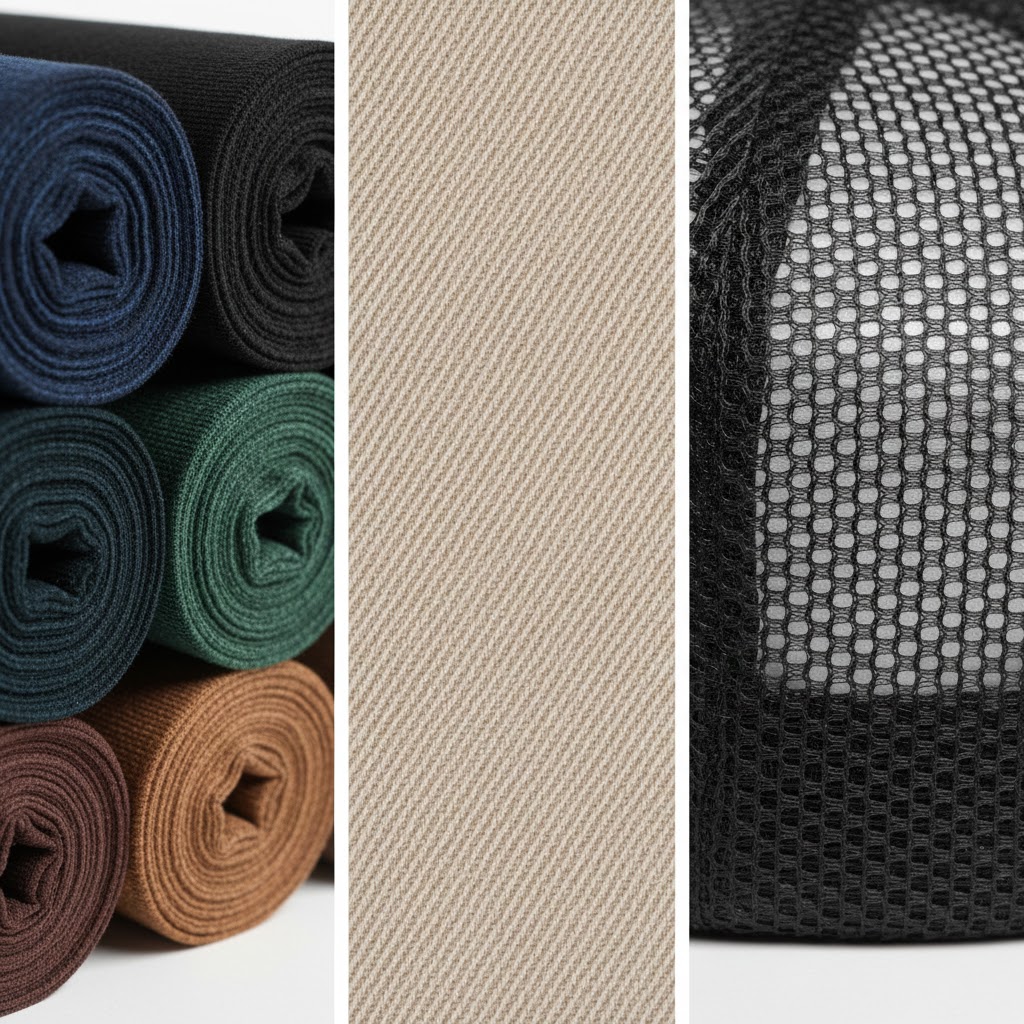

Which fabrics work best for premium custom hats?

For premium custom hats, fabric choice is less about trends and more about how the hat will be used, sold, and perceived by the end customer. In the U.S. market, buyers care not only about look and feel, but also durability, comfort, and consistency across repeat orders.

The right fabric influences structure, embroidery quality, breathability, and how the hat holds up after months of regular wear. Choosing incorrectly often shows up later as poor sell-through, customer complaints, or costly reorders.

Cotton Twill: The Go-To for Lifestyle and Retail Brands

CoHigh-density cotton twill remains the most reliable option for lifestyle and promotional caps. It offers a balanced combination of comfort, structure, and embroidery stability—especially important for brands selling through retail or DTC channels.

Common options include:

- Chino or brushed cotton for a clean, everyday look

- Heavier twill weights for better shape retention and durability

- Organic cotton for brands with sustainability positioning

For many U.S. brands, cotton twill works because it feels familiar, wears comfortably, and performs consistently across large production runs.

Performance Fabrics: Built for Active and Outdoor Use

For sports, fitness, or outdoor-focused hats, technical fabrics are often a better fit. Moisture-wicking polyesters and engineered meshes are designed to manage heat, sweat, and airflow in more demanding environments.

Typical choices include:

- Performance mesh for ventilation and cooling

- Ripstop or nylon blends for rugged or utility-focused styles

- Stretch fabrics for improved fit and comfort

Using a lifestyle fabric in an active-use product is a common mistake—and one that often leads to negative reviews or returns when the hat doesn’t perform as expected.

Key Takeaway:Fabric choice defines how your custom hats are worn, perceived, and reordered.

Selecting materials based on real use cases—not just appearance—helps protect brand value and reduces downstream issues in the U.S. market.

| Fabric Type | Best Use Case | Why Brands Choose It |

|---|---|---|

| Cotton Twill | Lifestyle / Retail | Comfort, structure, embroidery reliability |

| Performance Mesh | Sports / Active | Breathability and moisture control |

| Ripstop / Nylon | Outdoor / Utility | Durability with reduced weight |

How do you choose the crown style for custom hats?

Choosing the crown style for custom hats is less about preference and more about how the hat is expected to look, wear, and sell in the market. For U.S. brands, the decision usually comes down to whether the hat needs to project structure and visibility—or comfort and a relaxed feel.

At a practical level, crown style affects logo presentation, fit, and how the hat holds its shape over time. Getting this wrong often shows up later as weak shelf appeal or customer feedback that the hat “doesn’t sit right.”

Structured Crowns: Built for Shape and Visibility

Structured crowns use internal buckram to maintain a firm, upright profile. This style is commonly chosen for snapbacks, trucker hats, and promotional caps where branding needs to stay sharp and visible.

Key characteristics include:

- Consistent shape even when not worn

- Strong support for large or 3D embroidery

- Higher-profile options that stand out on display

- Reinforced front panels for durability

For many U.S. brands, a structured crown works best when the logo is a central selling point and visual impact matters.

Unstructured Crowns: Relaxed and Wear-In Comfort

Unstructured crowns rely on the natural drape of the fabric, creating a softer, more casual silhouette. This style is common in dad hats and heritage-inspired designs where comfort and ease matter more than rigidity.

Typical benefits include:

- Lower-profile fit that conforms to the wearer’s head

- Soft feel with no stiff front panel

- Easy packability for travel or everyday use

- Ideal pairing with washed or distressed fabrics

Brands targeting lifestyle, fashion, or vintage aesthetics often prefer unstructured crowns because they feel broken-in from day one.

Key Takeaway

Crown structure determines how your custom hats are perceived at first glance.

Structured crowns emphasize visibility and polish, while unstructured crowns signal comfort and casual appeal. The right choice depends on how your target customer expects the hat to look and feel.

Crown Type Internal Support Best For Structured Buckram reinforced Logos, retail display, promotional use Unstructured No reinforcement Lifestyle wear, vintage or casual brands

How do you choose a bill for custom hats?

Choosing the right bill for custom hats comes down to how the hat is expected to be worn and perceived by the end customer. The bill isn’t just for sun protection — it plays a major role in defining the hat’s style category and market positioning.

For most U.S. brands, the decision starts with silhouette.

Flat vs. Curved Visors

Flat bills are commonly used in streetwear, lifestyle, and modern athletic hats where a sharp, contemporary look matters. Curved bills, on the other hand, signal a more traditional or outdoor-inspired style and are often associated with baseball caps and performance wear.

Common options include:

- Flat bills for a modern, retail-forward look

- Pre-curved bills for a classic, sport-oriented fit

- Slightly curved bills to balance style and everyday comfort

- Multiple stitch rows to add structure and a more premium feel

Many brands now choose a slight curve to avoid looking overly trend-driven while still appealing to a broad audience.

Under-Visor and Edge Details

Bill customization also offers subtle ways to differentiate your hats without competing with the front logo. Details like sandwich brims or under-visor color changes add depth while keeping branding clean.

Typical choices include:

- Contrast sandwich layers for understated branding

- Dark under-visors to reduce glare

- Vintage-inspired colors for heritage styles

These details are often noticed after purchase, reinforcing perceived quality and thoughtful design.

Key Takeaway

The bill defines the hat’s category before the logo does.

Choosing the right shape and details ensures your custom hats align with how customers expect them to look, wear, and perform.

| Bill Feature | Option A | Option B |

|---|---|---|

| Shape | Flat (Modern) | Curved (Classic) |

| Undervisor | Match color | Contrast color |

| Edge Detail | Plain | Sandwich layer |

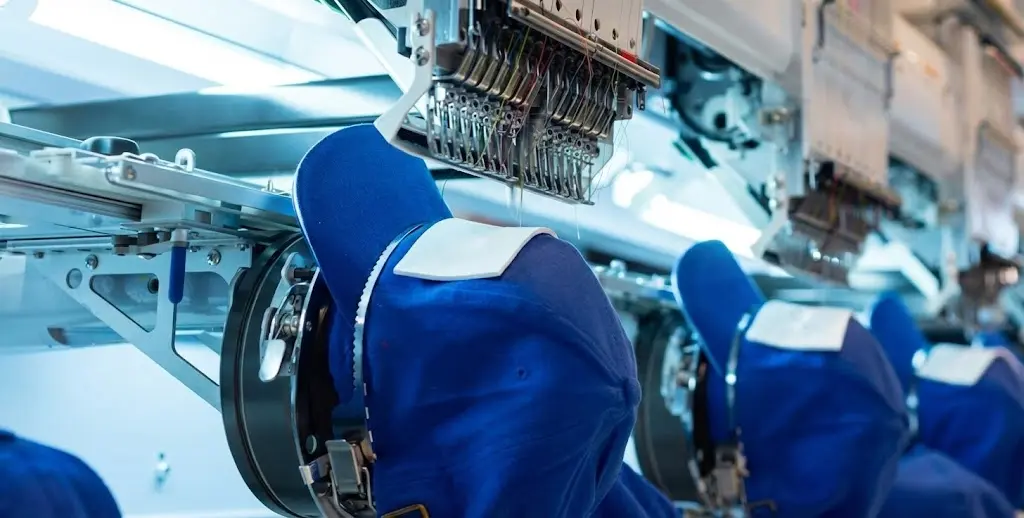

What branding techniques define high-end custom hats?

High-end custom hats are defined less by logo size and more by how branding is executed. In the U.S. market, premium headwear relies on techniques that add depth, texture, and durability—details that signal quality the moment a customer picks up the hat.

Instead of flat printing, advanced branding methods create a tactile experience that separates retail-grade hats from promotional giveaways.

The Power of 3D Puff Embroidery

3D puff embroidery uses a foam insert beneath the stitching to create a raised, dimensional effect. It works best for bold, simplified logos and is commonly used on structured front panels where shape needs to stay crisp.

Key advantages include:

- Strong visual presence that draws attention on shelves

- Clean, structured finish for premium positioning

- Higher perceived value compared to flat embroidery

Because it requires higher stitch density and tighter quality control, 3D puff embroidery is often associated with brands that invest in long-term product quality.

Specialized Patches and Labels

When logos include fine text, complex shapes, or multiple colors, patches and labels offer greater precision than embroidery alone.

Common options include:

- Woven patches for sharp detail and readability

- Leather patches for rugged or heritage styles

- PVC or rubber patches for durability and outdoor use

These techniques allow brands to preserve design integrity while maintaining consistency across large production runs.

Key Takeaway

Premium branding techniques turn a basic cap into a retail-ready product.

The right method enhances durability, improves perceived value, and reinforces brand positioning—especially in competitive U.S. markets.

| Technique | Visual Impact | Best Use Case |

|---|---|---|

| 3D Puff Embroidery | High, textured | Bold logos, structured hats |

| Woven Patch | Clean, precise | Detailed logos, small text |

| Leather / PVC Patch | Premium, durable | Heritage or outdoor styles |

What closure options are available for custom hats?

Choosing a closure for custom hats is not just a functional decision — it directly affects product positioning, inventory flexibility, and customer comfort. In the U.S. market, closure type often signals whether a hat is streetwear, lifestyle, or utility-focused before the logo is even noticed.

The right closure balances ease of wear with the expectations of your target audience.

Snapbacks: Flexibility and Scale

Plastic snap closures remain the most widely used option because they fit a broad range of head sizes and simplify inventory management. For brands scaling quickly, snapbacks reduce size complexity while maintaining durability.

Common reasons brands choose snapbacks include:

- One-size-fits-most convenience

- Fast, intuitive adjustment for consumers

- Durable plastic options, including soft-touch finishes

- Color-matching or contrast styling for visual impact

For many U.S. brands, snapbacks offer the best balance between cost control and mass-market appeal.

Metal Buckles and Fabric Straps: Premium Positioning

Fabric straps with metal buckles are typically used in lifestyle and premium caps where aesthetics and tactile quality matter more than universal fit. This closure style adds refinement and pairs well with relaxed silhouettes like dad hats.

Typical features include:

- Metal sliders or buckles (brass, matte black, or silver)

- Fabric or leather straps for a finished look

- Tuck-in strap ends to keep the back clean

In this category, hardware quality matters. Low-grade buckles can undermine an otherwise premium product.

Key Takeaway

Closure choice affects both retail perception and operational efficiency.

Snapbacks prioritize flexibility and scale, while metal buckles elevate perceived value and style.

| Closure Type | Style Category | Best For |

|---|---|---|

| Plastic Snap | Streetwear / Sport | Broad audiences, fast scaling |

| Metal Buckle | Lifestyle / Premium | Fashion-focused brands |

| Hook-and-Loop | Utility / Active | Functional or workwear use |

Why are internal details vital for custom hats?

Internal details are what separate retail-grade custom hats from low-end promotional products. While customers may not notice these elements at first glance, they strongly influence comfort, perceived quality, and brand trust over time.

For U.S. brands, internal finishes often determine whether a hat feels thoughtfully made—or cheaply assembled—after extended wear.

Seam Taping: Hidden Branding and Structure

Custom seam taping reinforces internal seams while offering a subtle branding opportunity. When done well, it improves durability and leaves a strong impression when customers inspect the hat up close.

Common applications include:

- Printed brand names or logos on internal tape

- Clean, smooth finishes to reduce skin irritation

- Color contrast for a refined, premium feel

When a customer turns a hat inside out, these details quietly confirm that the product was made with intention.

Sweatbands: Comfort Drives Repeat Wear

The sweatband is the only part of the hat in constant contact with the wearer, making it critical for comfort and long-term satisfaction. Low-quality sweatbands are a common source of complaints, even when the exterior looks premium.

Typical upgrades include:

- Moisture-wicking materials for all-day wear

- Added padding for comfort and fit stability

- Antimicrobial treatments for hygiene

A well-designed sweatband reduces discomfort and helps ensure the hat is worn repeatedly—not abandoned after a few uses.

Key Takeaway

Internal details are where quality is felt, not just seen.

Seam taping and sweatband choices reinforce brand credibility, improve comfort, and support higher perceived value in the U.S. market.

| Internal Detail | Primary Function | Brand Impact |

|---|---|---|

| Seam Taping | Reinforcement | Professional finish |

| Sweatband | Comfort | Customer satisfaction |

| Woven Label | Identification | Authenticity |

How do you manage quality control for custom hats?

Managing quality control for custom hats is about protecting your inventory investment before problems reach the warehouse. For U.S. brands, effective QC isn’t a single checkpoint—it’s a system that starts before production and continues through final inspection.

Without clear quality controls, issues like misaligned embroidery, inconsistent sizing, or color variation often surface only after delivery—when they’re the most expensive to fix.

Using AQL Inspections to Control Risk

AQL (Acceptance Quality Limit) inspections are widely used in retail apparel to verify batch quality without inspecting every unit. Many brands require AQL 2.5 as a practical balance between coverage and efficiency.

Typical checks include:

- Random sampling from the production lot

- Limits on major and minor defects

- Stitching alignment and symmetry

- Colorfastness and basic durability testing

Relying solely on factory self-inspection increases risk. Independent oversight provides an additional layer of accountability—especially for larger orders.

Pre-Production Samples: The Non-Negotiable Step

A full production run should never begin without an approved pre-production sample (PPS). This is the final point where design intent and factory execution must fully align.

Key elements to verify include:

- Logo placement and embroidery quality

- Fabric color, weight, and hand-feel

- Closure functionality and fit

- Internal labels and finishing details

Most large-scale production issues can be traced back to skipped or rushed sampling decisions.

Key Takeaway

Quality control isn’t about catching defects—it’s about preventing unsellable inventory.

A structured QC process protects your brand, your cash flow, and your ability to reorder with confidence.

| QC Stage | Primary Action | Risk It Reduces |

|---|---|---|

| Fabric Sourcing | Material testing | Fading, tearing |

| Pre-Production | Physical sample approval | Design mismatch |

| Final Inspection | AQL 2.5 check | Batch inconsistency |

How should you package and ship custom hats?

Packaging and shipping custom hats isn’t just about protection—it’s about delivering inventory that arrives retail-ready without unexpected cost or damage. For U.S. brands, poor packaging often shows up later as crushed crowns, higher return rates, or inflated freight bills.

The goal is simple: protect shape, control logistics costs, and maintain brand presentation through transit.

Retail-Ready Packaging: Protect the Shape, Elevate the Brand

Premium custom hats require internal support to prevent deformation during shipping. Cardboard inserts and proper packing methods help maintain crown structure while creating a better unboxing experience.

Common retail-ready elements include:

- Cardboard crown inserts to prevent crushing

- Custom hang tags or tissue paper for brand presentation

- Individual boxes for limited or premium releases

Well-executed packaging ensures hats arrive in sellable condition and reinforces perceived quality the moment the box is opened.

Bulk Shipping: Control Dimensional Weight and Risk

Hats are lightweight but bulky, making them sensitive to dimensional weight charges. Efficient carton sizing and protective packing reduce freight costs while minimizing transit damage.

Key considerations include:

- Optimized carton sizes to reduce empty space

- Sturdy outer cartons for stacking protection

- Moisture control for long-distance transit

- Clear packing lists to avoid customs delays

Poor logistics planning often leads to damaged goods or unexpected shipping fees that cut into margins before products reach the market.

Key Takeaway

Packaging and logistics are the final quality check before your hats reach customers.

The right approach protects product integrity, controls shipping costs, and ensures your custom hats arrive ready for retail or fulfillment.ndition.

| Packaging Element | Purpose | Business Impact |

|---|---|---|

| Cardboard Insert | Shape retention | Reduces damage claims |

| Retail Packaging | Brand presentation | Higher perceived value |

| Optimized Cartons | Freight efficiency | Lower shipping costs |

Who is the ideal target market for custom hats?

The ideal target market for custom hats depends on how the product will be used, distributed, and evaluated after purchase. In the U.S. market, different buyer types prioritize different outcomes—whether that’s brand visibility, durability, or resale value.

Understanding which segment you’re designing for is critical, because it influences everything from fabric selection to crown structure and price point.

Corporate and Event Buyers

Corporate clients typically use custom hats for employee uniforms, trade shows, golf outings, or promotional events. For this segment, consistency, comfort, and professional appearance matter more than trend-driven design.

Common priorities include:

- Classic silhouettes that suit a wide audience

- Durable, easy-care fabrics for repeated wear

- Adjustable closures to simplify sizing

- Bulk-friendly designs that scale efficiently

For many corporate buyers, a well-made hat functions as long-term brand exposure rather than a one-time giveaway.

Fashion and Streetwear Brands

Fashion-focused and streetwear brands operate very differently. These buyers are driven by differentiation, limited releases, and strong visual identity. Custom hats in this segment are treated as retail products, not promotional items.

Typical preferences include:

- Structured crowns for bold logo presentation

- Flat or slightly curved bills for modern styling

- Specialty fabrics like corduroy or washed cotton

- Advanced branding techniques, including 3D embroidery

Here, perceived value and design execution directly affect sell-through and pricing power.

Key Takeaway

Your target market determines how your custom hats should look, feel, and perform.

Defining the buyer segment upfront ensures design choices align with real-world use and customer expectations.

| Market Segment | Primary Priority | Typical Style |

|---|---|---|

| Corporate / Events | Consistency & durability | Classic, adjustable caps |

| Fashion / Streetwear | Differentiation & branding | Structured snapbacks |

| Sports / Active | Performance & comfort | Mesh or technical styles |

By aligning your design decisions with the real needs of your audience, you reduce production risk and build a headwear line that performs consistently in the market.

If you’re evaluating manufacturing options or pressure-testing your current setup, having the right production partner early often makes the biggest difference—long before pricing or volume become the main concern.

Frequently Asked Questions

Can I order a sample before committing to bulk production?

Yes. A physical pre-production sample (PPS) is a standard step before any bulk run. It allows you to verify construction, materials, branding, and fit against your approved tech pack before moving forward.

What’s the best fabric for a summer-focused hat brand?

For warm-weather use, most U.S. brands choose lightweight cotton twill or performance polyester mesh. These materials offer better breathability and moisture management, making them more comfortable for extended wear.

How do I know if my logo is suitable for 3D puff embroidery?

3D puff embroidery works best with bold shapes and sufficient line thickness. If your artwork is too detailed, a woven patch or flat embroidery may produce cleaner results. Artwork review at the sampling stage helps determine the best option.

Can internal seam taping be customized with my brand name?

Yes. Custom internal seam taping is available for full custom projects and is commonly used to reinforce construction while adding subtle, premium branding inside the hat.

How do you prevent hats from getting crushed during shipping?

We use internal cardboard crown supports along with reinforced outer cartons to protect shape during transit. This helps ensure hats arrive in retail-ready condition, even for long-distance shipments.